Willkommen im

Ausstellerportal

der productronica 2023

Zu den Ausstellern

Mycronic AB

Discover the next generation of productivity

Join us in defining a new era of agility at productronica 2023.

TOPLINE Corporation

Neueste Geflecht-verstärkte Lotsäulen

Lotsäulen sind zuverlässiger als Lotkugeln auf BGA-Gehäusen. Erfahren Sie mehr.

Ersa GmbH

FUTURE SERVICES & ADDED VALUES

ERSA - Systemlieferant für smarte Produktionsprozesse & perfekte Lötverbindungen

◦

◦

◦

SEMICON Europa

Hier finden Sie alle Aussteller der SEMICON Europa, der europäischen Plattform für die Halbleiterfertigungsindustrie.

Anzeige

Programmüberblick zur productronica

Das Rahmenprogramm auf der productronica, der Weltleitmesse für Entwicklung und Fertigung von Elektronik.

Top-Aussteller

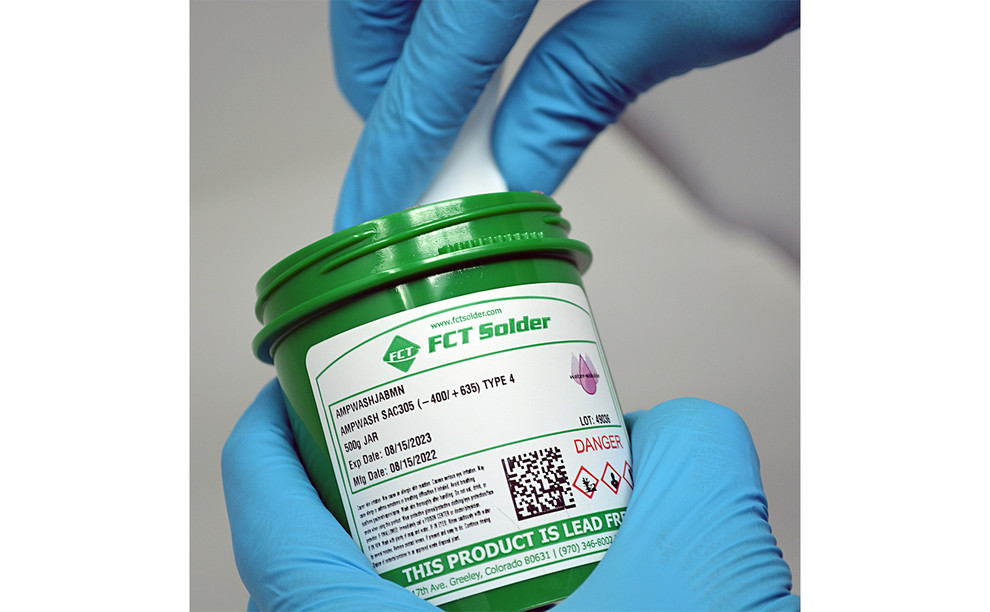

FCT Solder

High-quality solders that perform!

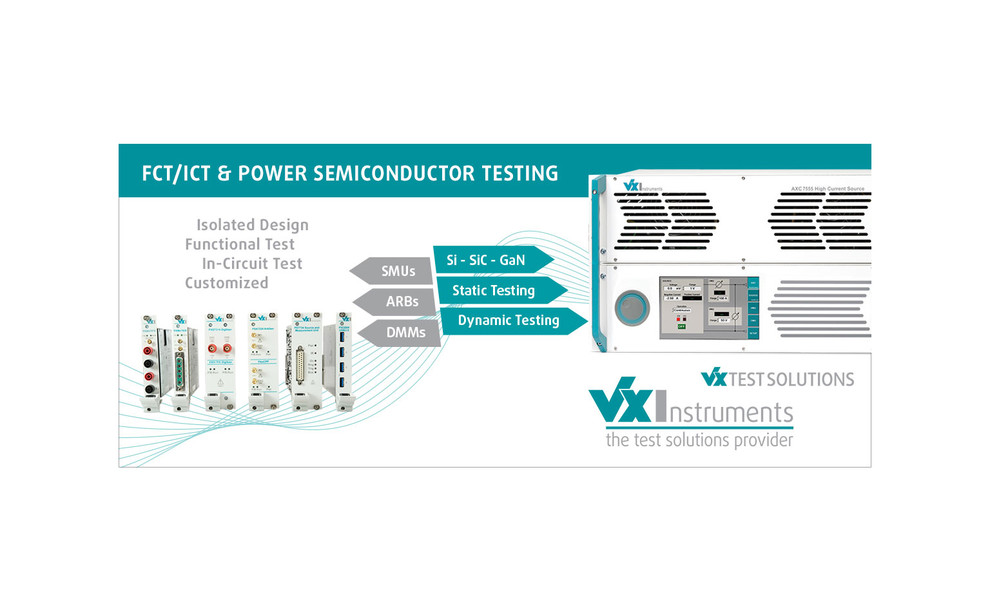

VX Instruments GmbH

VX Instruments - the test solutions provider

ELANTAS Europe GmbH

Electronic Protection

Arch Systems

Manufacturing Data & Analytics

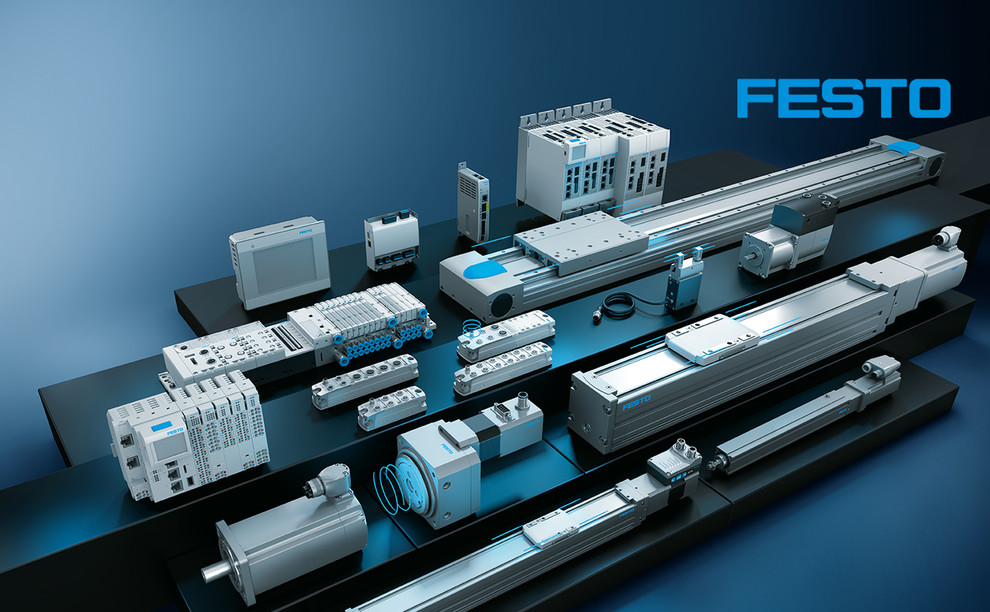

Festo SE & Co. KG

Automatisierung für die Industrie

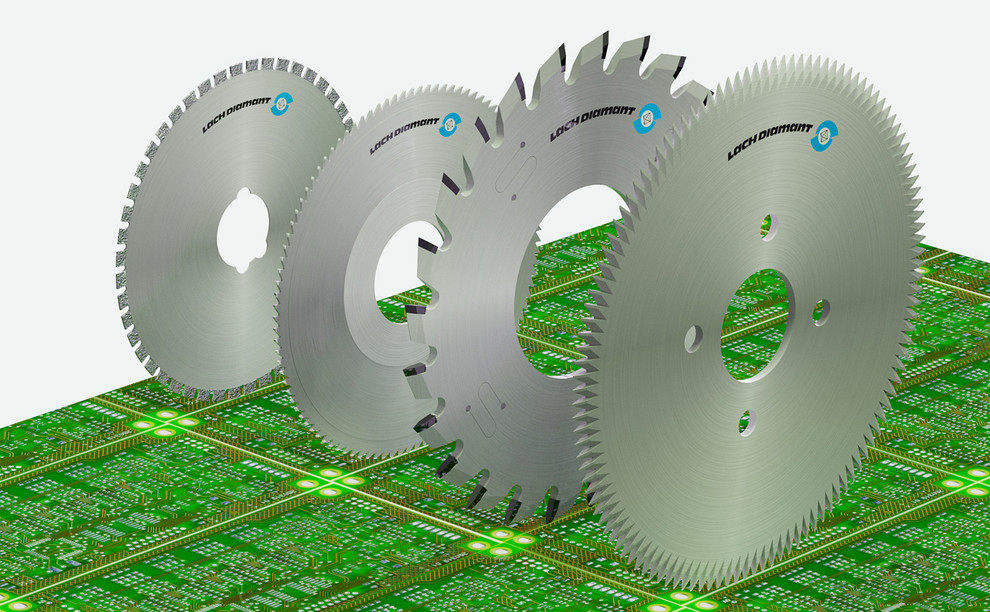

LACH DIAMANT Jakob Lach GmbH & Co. KG

Diamant- und Hartmetallwerkzeuge für PCB

Zoller + Fröhlich GmbH

Kabelverarbeitung von Zoller + Fröhlich

EVIDENT Europe GmbH

Mikroskope für die Elektronikindustrie

Scheugenpflug GmbH

Dosieren in Perfektion

JBC Soldering SL

JBC Löt- und Rework-Ausrüstung

Nutek Europe B.V.

NEED CLEVER ADJUSTED PRODUCTION LINES?

Hakko Corporation

Experience a whole new level!

Kretz+Wahl Gebäudetechnik GmbH & Co. KG BU Reinraum

Reinraum-Systeme nach Maß

Komax Group

Innovative Kabelverarbeitungslösungen

Virginia Panel Corporation (VPC)

VPC- New High Power Interconnect!

MBtech

MBtech, your cleaning expert-partner

Yamaha Robotics

Discover Yamaha Intelligent Factory

XTPL S.A.

XTPL

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

Produkte/Dienstleistungen

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

Produktgalerie

KIST + ESCHERICH GmbH

Sauberkeit neu definiert

eurolaser GmbH

Universelle Laserbearbeitungssysteme + neue Kamera

EIIT

INLINE-HANDLING-LÖSUNGEN

Plasmatreat GmbH

REDOX-Tool

EVIDENT Europe GmbH

Augmented-Reality-Mikroskopsystem SZX-AR1

Zoller + Fröhlich GmbH

Integrierte Lösungen

LACH DIAMANT Jakob Lach GmbH & Co. KG

PKD Kerbritzfräser

MPK Kemmer GmbH PCB Tools

PCB Tools

Transition Automation, Inc.

Permalex Infused Metal Squeegees for Advanced SMT

Weidinger GmbH

Modulare Robotik- und Automationslösungen

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

Anwendungsgebiete

◦

◦

◦

◦

◦

◦

◦

◦

Videos

TOPLINE Corporation

Komax Group

BUSCH Microsystems Consult GmbH

EVIDENT Europe GmbH

Zoller + Fröhlich GmbH

Transition Automation, Inc.

VX Instruments GmbH

Mycronic AB

OptiMel Schmelzgußtechnik GmbH

Nutek Europe B.V.

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦